Exploring the Role of Pipette Measurement in Quality Assurance Processes

Pipette measurement plays a critical role in quality assurance processes across various industries. From pharmaceuticals to food and beverage, accurate measurement is imperative for ensuring product quality and compliance with regulatory standards. In this comprehensive guide, we delve into the significance of pipette measurement in quality assurance and its impact on overall product integrity.

The Significance of Pipette Measurement in Quality Assurance

Precision in Measurement: Ensuring Accurate Results

In the realm of quality assurance, precision is paramount. measuring pipette serves as a cornerstone in achieving accuracy and consistency in laboratory testing procedures. Whether it’s dispensing precise volumes of liquids for chemical analysis or conducting intricate experiments, the reliability of pipette measurement directly influences the validity of test results. Even minor discrepancies in measurement can lead to significant deviations in outcomes, potentially compromising product quality and safety.

Compliance and Regulatory Standards: Upholding Quality Assurance Protocols

In regulated industries such as pharmaceuticals and healthcare, adherence to strict compliance and regulatory standards is non-negotiable. Pipette measurement plays a pivotal role in meeting these requirements by ensuring that all testing processes align with established protocols and guidelines. From Good Laboratory Practices (GLP) to Good Manufacturing Practices (GMP), precise pipetting techniques are indispensable for maintaining data integrity and regulatory compliance.

Enhancing Efficiency and Productivity: Streamlining Laboratory Operations

Efficiency and productivity are key drivers of success in any laboratory setting. By utilizing advanced pipette measurement technologies, laboratories can streamline their operations and optimize workflow processes. Automated pipetting systems and electronic pipettes enable rapid and accurate dispensing of samples, reducing the likelihood of human error and minimizing downtime. This not only enhances overall efficiency but also maximizes productivity, allowing laboratories to meet demanding deadlines without compromising on quality.

Quality Control and Assurance: Safeguarding Product Integrity

The foundation of quality assurance lies in rigorous quality control measures. Pipette measurement serves as a critical component of quality control protocols, ensuring that every stage of the manufacturing process meets predefined quality standards. By meticulously monitoring sample volumes and concentrations, laboratories can identify and rectify potential deviations before they escalate into larger issues. This proactive approach to quality assurance not only safeguards product integrity but also instills confidence in consumers and stakeholders alike.

Read also: Sailing Success with Sales Recruitment Agencies in Toronto

Leveraging Technology for Precision and Accuracy

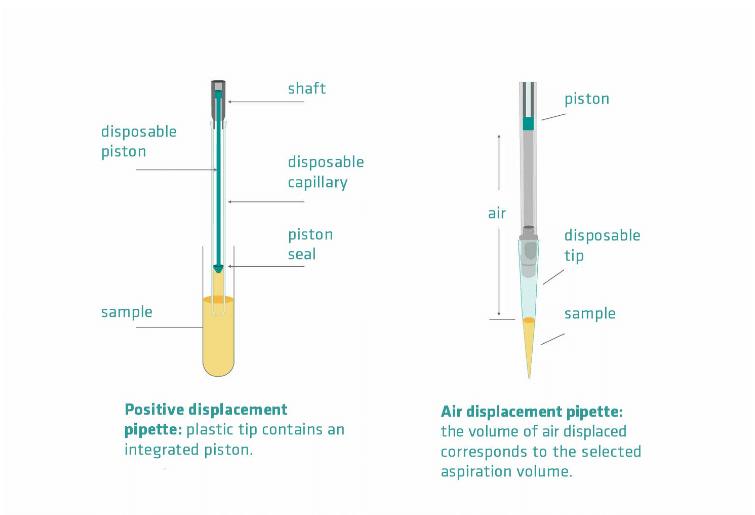

Innovation in pipette measurement technology continues to revolutionize the field of quality assurance. From ergonomic designs to intuitive user interfaces, modern pipettes are engineered to deliver unparalleled precision and accuracy. Features such as adjustable volume settings, electronic calibration, and real-time data recording empower laboratories to achieve unparalleled levels of reliability and consistency in their testing procedures. By embracing these technological advancements, organizations can elevate their quality assurance practices to new heights of excellence.

FAQs

FAQ 1: What factors can affect the accuracy of pipette measurements?

Answer: Several factors can influence the accuracy of pipette measurements, including temperature variations, improper calibration, and user technique. It’s essential to maintain optimal laboratory conditions and regularly calibrate pipettes to ensure reliable results.

FAQ 2: How often should pipettes be calibrated?

Answer: Pipettes should be calibrated at regular intervals, typically every 6 to 12 months, depending on usage frequency and manufacturer recommendations. Additionally, calibration should be performed whenever there are significant changes in environmental conditions or after any maintenance or repair work.

FAQ 3: Can pipette measurement be automated?

Answer: Yes, many modern pipettes feature automation capabilities, allowing for programmable dispensing of samples and integration with laboratory automation systems. Automated pipetting not only enhances accuracy but also improves efficiency by reducing manual labor and minimizing the risk of repetitive strain injuries.

Conclusion:

In conclusion, the role of pipette measurement in quality assurance processes cannot be overstated. By ensuring precision, compliance, and efficiency, pipettes play a vital role in upholding the highest standards of product quality and safety. As industry leaders in materials testing equipment and laboratory supplies, certifiedmtp.com remains committed to providing high-quality solutions that empower laboratories to excel in their quality assurance endeavors. Whether it’s through our comprehensive range of pipettes or our extensive lineup of testing equipment, we are dedicated to exceeding our customers’ expectations and driving excellence in every aspect of quality assurance.